When you imagine how to build a house, usually the materials that come to mind are concrete, steel, wood, and standardized materials with typical building methods of the last few hundred years. Brick by brick, houses are built through the labours of construction workers and the guidance of managers who handle material escalations and budgeting.

However, over the last few decades, a new wave of thinking has been applied to the construction world. What if we could use typical building materials, such as concrete, and form them in ways that challenge construction norms? What if we build houses layer by layer, like a soft serve machine extruding ice cream onto a waffle cone at McDonald’s? (except this time it is not always broken and is reliable)

I first discovered this idea through my interest in 3D printing, where the typical material being used is plastic. 3D printing has existed, to my surprise, since the early 1980s, first patented by a Japanese Automobile designer named Hideo Kodama. Kodama’s printing method uses UV light to harden a photopolymer layer by layer, creating an object, much like resin printers today. In 1989, Fused Deposition Modelling (FDM) printing emerged, a method of printing solid material layer by layer that is considered safer by modern standards. Researchers, institutions, and hobbyists can finally start considering using conventional printing materials, such as plastic or metal.

So, now we are onto the present day, where I was printing with plastics, such as PLA, PETG, ABS, and many other filaments that are questionable to the air I was breathing in the house. I then came across Icon Build, merely by accident, and it opened a new door for me in 3D printing, and inspired me to create a 3D printer that prints clay.

ICON creates these giant 3D-printing machines that print facades for houses that can withstand gale-force winds, using 3D-printed pillars and structural elements. When I first thought about 3d printing with concrete, I was imagining a much more dull, rough-looking structure, but this company is defying all my assumptions. The houses built by ICON, such as the “Mueller” in Austin, Texas, have a modern look inside and out, and the function of a normal home. I was quite shocked at how modern all the buildings looked interiorly and exteriorly, and it made me think about what I can do myself for a project.

This is when I discovered clay 3D printing. Clay is often used in construction, in the form of bricks, and it is also used in many early, more primitive housing of the past. I wondered, if concrete can be made in a way to have it printed out through a nozzle, why can’t clay be done the same way? And that is exactly what I did. I researched different types of clays to check for their properties, and decided on earthenware clay as the main material, as it is commonly used in brick making.

Next is the physical structure that can print the clay. I had years of 3D printing experience and modding 3D printers, though I never physically built one myself, especially not one where clay is the material. Clay had several problems that came with it:

- Viscosity of clay, too thick, then it won’t print, too viscous, it won’t harden.

- Pressure to push out the clay. The distance between where the clay is stored and the nozzle head needs to be as short as possible, or else a lot of torque needs to be applied to the motors to get the clay to where it needs to be.

- Adhesion and layer lines. Adhesion to the base is essential, and the adhesion between layers is also. Making the layer lines too thin will cause the print to sag under vertical pressure at the nozzle, but too thin lines will cause the layers not to adhere.

These were the three main problems that came with making the printer, and I struggled very much to check them off the list one by one.

During the time of making the printer, not a lot of clay printers were on the market, and making one from scratch that wasn’t just modifying other printers was even harder to find tutorials and examples. However, after much searching, I found a Delta printer made by Taekyeom Lee, an Associate Professor of Graphic Design at Indiana University Bloomington. I was inspired by his earlier version of the Clay 3D printer (though now it seems he has improved a lot on the design of his new portfolio).

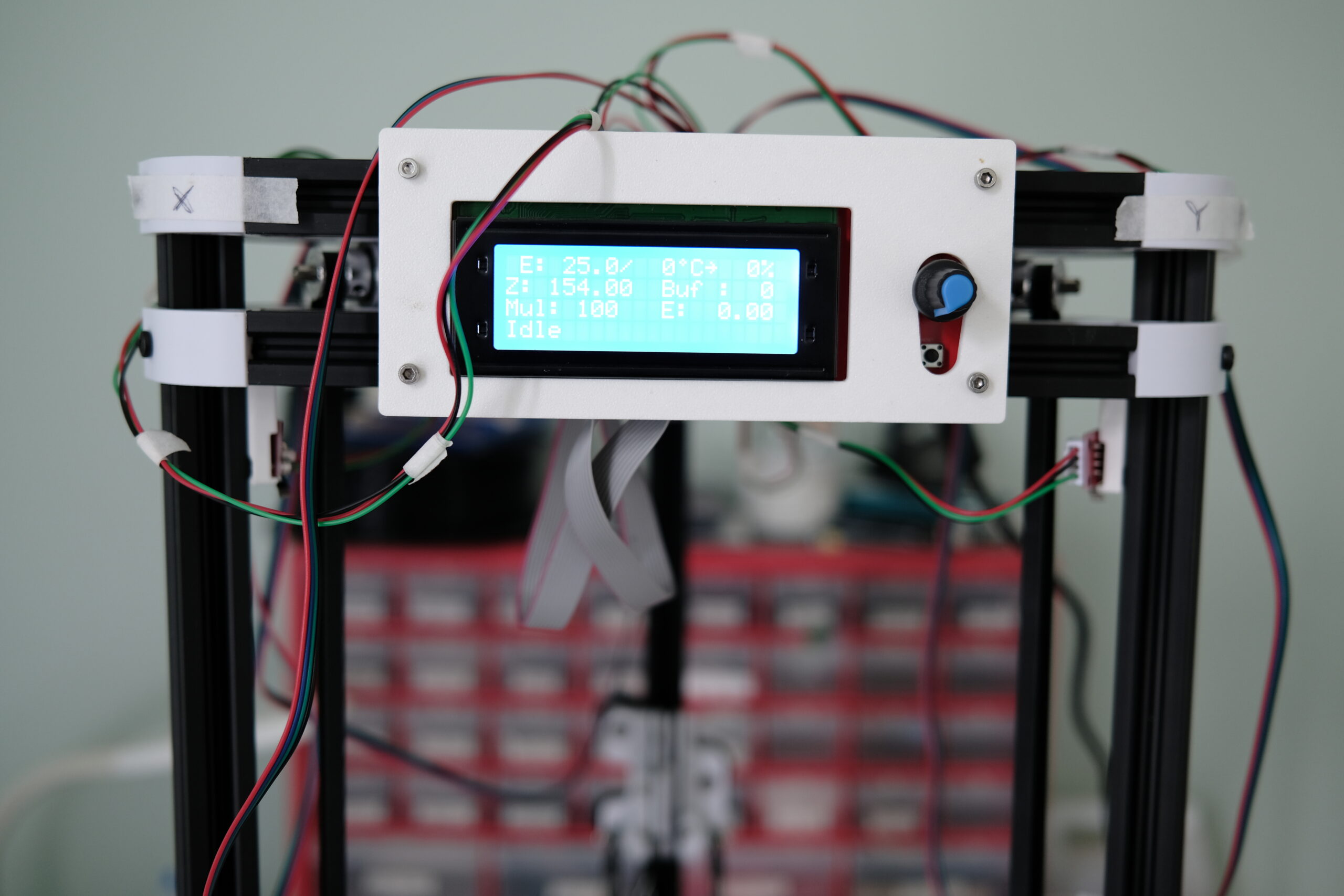

I collected parts based on his recommendations, and made a list of items, such as syringes, stepper motors, and electronic components, which are listed more on my LinkedIn from 2023. After breaking 3 motherboards, almost electrocuting myself countless times, it was finally made. The problem of viscosity was solved by mixing multiple samples with different moisture contents, and testing what percentage of water worked (and yes, it was as annoying and time-consuming as you may have imagined). The clay being pushed out was solved by attaching another through-shaft stepper motor connecting to a long threaded rod that had the rubber piston from the syringe. This way, the clay only needs to be pushed out from the syringe to the tip, and not connected by a tube like traditional FDM printers. Finally, the adhesion and layer lines were just a testing process, where the “quality” or thickness of the layers was adjusted based on what worked and what didn’t (and if it didn’t work, then I had to remix the clay to the proper proportion, and redo the whole process).

I found myself leaning somewhat away from the objective of the project, which was to learn more about 3D printed housing, and falling towards the software and hardware behind 3D printing. Though after some thought, I realized this is probably what the people who started 3D printing houses also struggled through. They had to take conventional 3D printing methods and identify problems and obstacles that had to be solved to achieve the final objective. They probably also struggled with the mixes of concrete, the transport of material from the mixer to the nozzle, as well as the adhesion lines and the structural integrity of the houses themselves. To finally see my prints working and not crumbling was not only an excitement that I still feel to this day, but it made me feel connected to the struggles of the engineers who were also trying new things.

In the end, I believed it was a great learning experience to expand on both my Civil Engineering knowledge and also my mechanical and electrical knowledge. At present, I am working more towards other goals and projects, though it does not take away from this experience that started in 2023, and I hope I keep doing projects not because I need to, but because I want to.

Leave a Reply